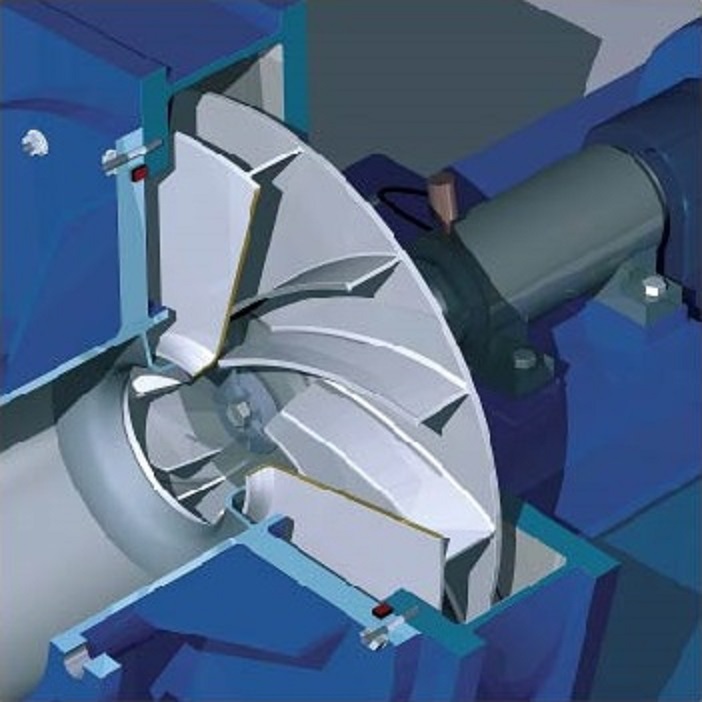

I specialize in designing complex mechanisms with simple parts. I use analysis techniques like strucural FEA and mold flow analysis during the design process to speed up the development process and avoid expensive production problems. I work with small or large businesses and startups.

I cut my teeth at John Deere, designing forestry equipment on the structures and hydraulics team. I then transitioned to Transact Technologies where I designed printers and touchscreen kiosks.

Sheet Metal

Injection Molded Plastics

Vacuum Formed Plastics

Aluminum & Plastic Extrusions

Tolerance Stackups

Castings

Complex Assemblies

Gears & Geartrains

Surfacing

Machined Components

Routed Systems

Hardware & Toolpaths

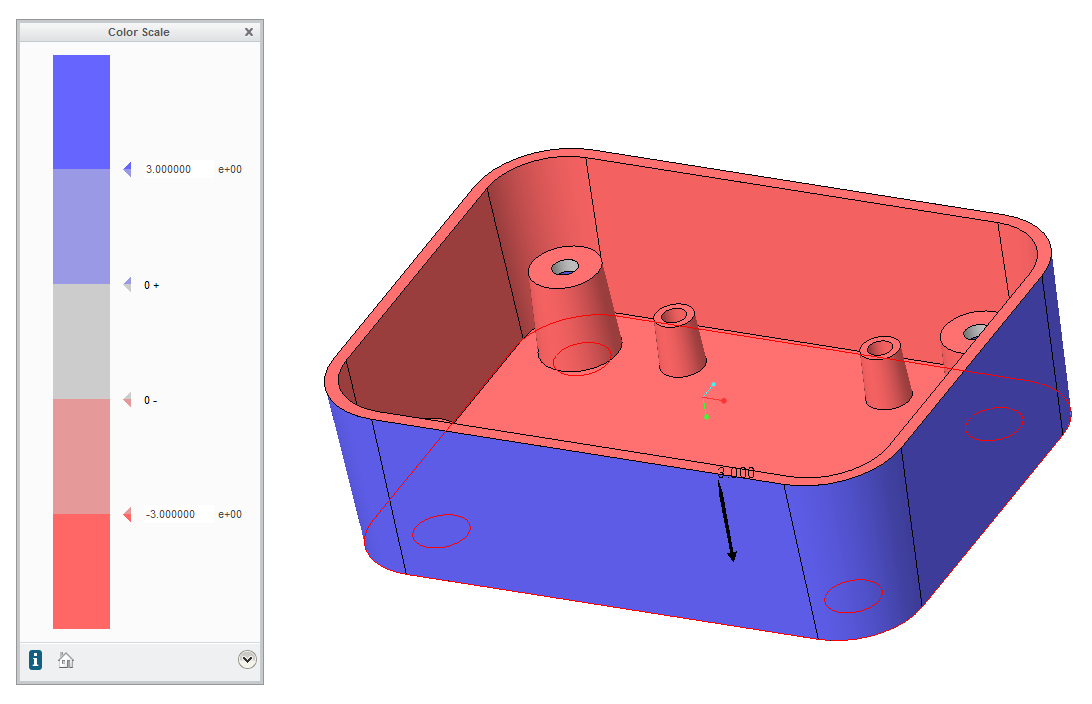

I use static FEA at all stages of the design process, often using it to guide the direction of the design. FEA can also help explain failure modes when building prototypes or in production.

Close

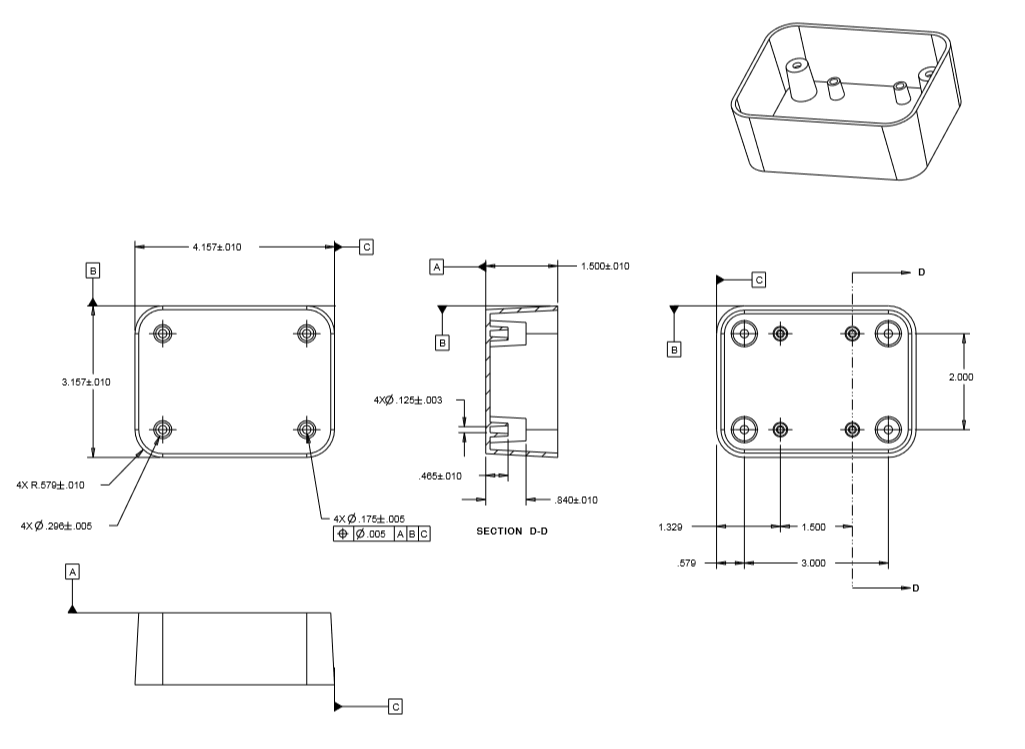

Good drafting and GD&T practices help communicate part requirements and drive manufacturing processes. I strive to produce economical designs with practical manufacturing processes in mind.

Close

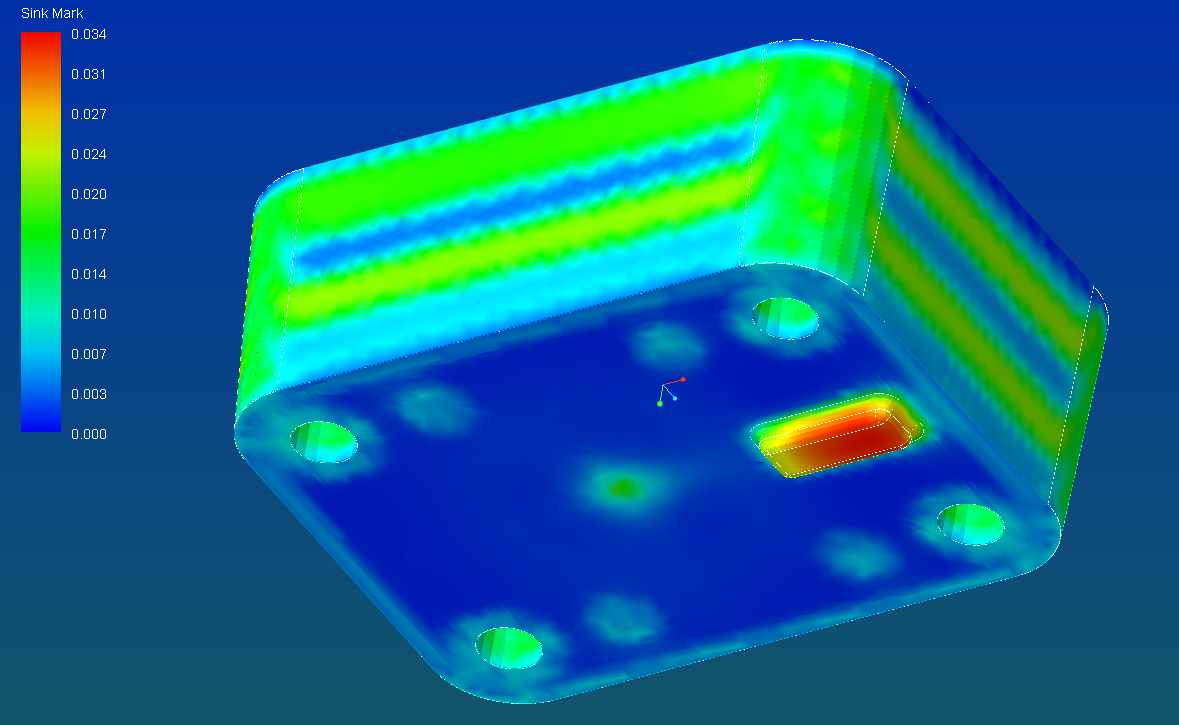

Mold flow analysis helps identify problems before tooling. I use automated tools to identify sink marks and verify suficient draft, ensuring proper mold release.

Close

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Mollitia neque assumenda ipsam nihil, molestias magnam, recusandae quos quis inventore quisquam velit asperiores, vitae? Reprehenderit soluta, eos quod consequuntur itaque. Nam.

Close

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Mollitia neque assumenda ipsam nihil, molestias magnam, recusandae quos quis inventore quisquam velit asperiores, vitae? Reprehenderit soluta, eos quod consequuntur itaque. Nam.

Close